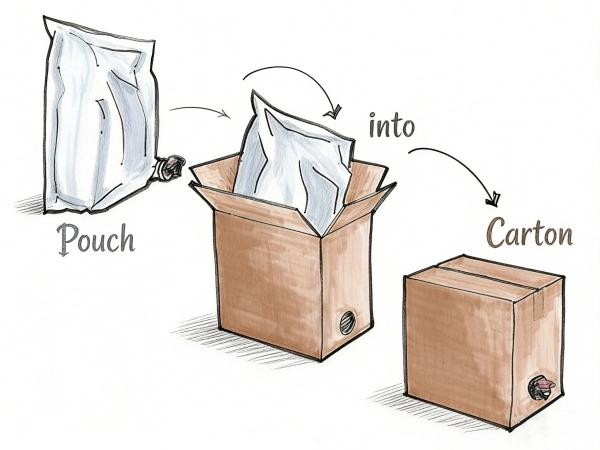

Bag-In-Box is a flexible packaging solution widely used for liquids such as beverages, food ingredients, chemicals, and industrial fluids. It typically consists of a multi-layer inner bag made from high-barrier films, a dispensing tap or valve, and an outer corrugated carton for protection and handling. Its core functions include safe storage, contamination prevention, extended shelf life, and convenient dispensing.

The overall quality of a Bag-In-Box is determined not only by material selection, but also by critical production processes such as precise film sealing, accurate valve insertion, stable welding strength, dimensional consistency, and leak-free performance throughout filling and transportation.

To achieve these quality requirements, Bag-In-Box making machines play a decisive role.

Integrated production capability: Bag-In-Box making machines combine automated bag forming, valve welding, precise sealing, and in-line quality control into a single, continuous production line.

High sealing accuracy: Precise sealing systems ensure strong, uniform welds, effectively reducing the risk of leakage and improving product safety.

Stable heat control: Advanced temperature regulation guarantees consistent sealing performance, even during high-speed or long-duration production.

Consistent output quality: Automated operation minimizes human error, resulting in uniform bag dimensions and stable product quality.

Reduced defect rates: Accurate process control significantly lowers the occurrence of sealing defects, misalignment, and material waste.

Improved production efficiency: High automation and optimized workflows enable faster production cycles and higher throughput.

If you are a Bag-In-Box manufacturer, Mingli recommends the following machine models:

| Model | ML-1300BIB | ML-1600BIB |

| Material Size | Film Width: 1350mm, Roll Diameter: 800mm | Film Width: 1600mm, Roll Diameter: 800mm |

| Bag Size | Longest 800mm per double, Maximum Width 1300mm | Longest 800mm per double, Maximum Width 1600mm |

| Fuselage Size | 20000mm×4890mm×2380mm | 26000mm×4890mm×2380mm |

| Fuselage Weight | 9T | 20T |

| Bag-making Speed | 18 pcs/min | 20×4 pcs/min |

You can use any of these machines to produce Bag-In-Box products, all of which deliver outstanding and consistent product quality. In addition, Mingli is able to provide customized adjustments across different machine models to match your specific production requirements.

Beyond producing high-quality Bag-In-Box packaging, customers who have previously invested in our bag making machines also highly praise their cost-saving performance and long-term operational efficiency.